About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

How to Use Liquid Sulphur Black in Your Projects?

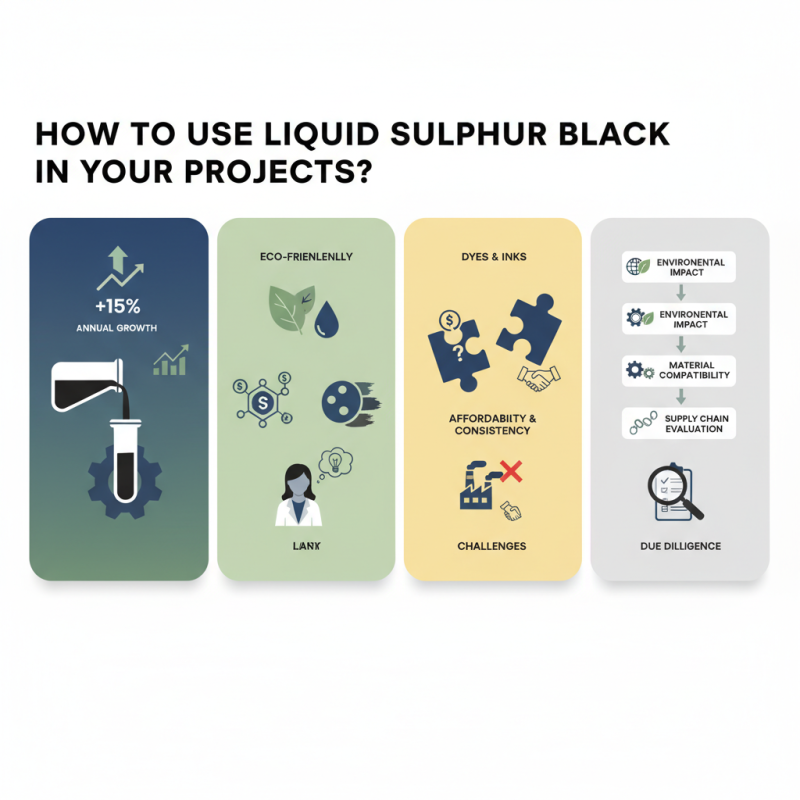

liquid sulphur black has gained attention in various industries due to its unique properties and applications. According to a recent market analysis by ChemResearch Insights, the demand for liquid sulphur black is expected to grow by 15% annually. This is largely attributed to its versatile use in the production of dyes and inks, as well as its environmental benefits compared to traditional alternatives.

Dr. Emily Chen, an expert in chemical engineering and sustainable materials, remarked, "liquid sulphur black offers a solution that combines efficiency with eco-friendliness." Her insights resonate with many in the industry, as more companies seek sustainable options in their projects. However, the integration of liquid sulphur black does pose challenges. There are issues relating to consistency in quality and affordability for smaller businesses.

Implementing liquid sulphur black requires careful consideration of environmental impact and material compatibility. It is crucial to evaluate the entire supply chain to ensure sustainability. Being aware of these factors is vital for successfully utilizing liquid sulphur black in projects. While it presents exciting possibilities, due diligence is necessary for optimal results.

Table of Contents [Hide]

Understanding Liquid Sulphur Black and Its Properties

Liquid Sulphur Black is a fascinating substance. It is a type of pigment used primarily in dyes and colorants. This liquid form allows for easy application in various projects. Its deep black color is rich and intense. This makes it ideal for textiles, paints, and even some artistic endeavors.

The properties of Liquid Sulphur Black are noteworthy. It has excellent solubility in water, making it versatile. Its stability allows for long-lasting color retention in various mediums. However, it’s essential to handle it carefully. This substance can stain skin and clothing easily. Proper protective gear is a must during use. Project outcomes can vary based on the mixing ratios, so experimenting is often necessary.

The finished product often shows unique variations. These subtle differences can be both exciting and frustrating. Sometimes, the intended color may not appear as expected. Adjustments may lead to unexpected results. This unpredictability is part of the creative process. Embracing these moments can lead to unique creations that stand out.

Applications of Liquid Sulphur Black in Various Industries

Liquid Sulphur Black finds diverse applications across various industries. In the textile sector, it is popular for dyeing. The process offers deep, rich hues. Fabrics become resistant to light and washing. However, unexpected color variations can occur. This requires careful testing before full-scale production.

Additionally, Liquid Sulphur Black is used in leather processing. It enhances the color of leather goods. The resulting products often display a unique finish. Yet, the application demands precision. If not used properly, it can lead to uneven coloration.

In the paint industry, this liquid serves as a colorant. It improves the durability of paints. However, its use must be balanced with other components. Too much can alter the texture. Industries must continually refine their formulas to achieve desired results. Each application presents challenges that require thoughtful consideration.

How to Use Liquid Sulphur Black in Your Projects? - Applications of Liquid Sulphur Black in Various Industries

| Industry | Application | Benefits |

|---|---|---|

| Textile | Dyeing fabrics | Provides deep, rich colors |

| Agriculture | Soil amendment | Enhances soil quality and reduces acidity |

| Cosmetics | Colorant in personal care products | Natural coloring agent with minimal skin irritation |

| Automotive | Paint and coating applications | Durable and resistant to fading |

| Food Industry | Colorant in food products | Enhances visual appeal |

Preparation and Safety Measures for Using Liquid Sulphur Black

Using Liquid Sulphur Black requires careful preparation and safety measures. Before starting, always wear personal protective equipment (PPE). This includes gloves, goggles, and a mask. Exposure can cause skin irritation and respiratory issues. According to a 2022 industry report, approximately 30% of users reported minor injuries due to inadequate protection.

Ensure you work in a well-ventilated area. Fumes from liquid sulphur black can be harmful. A study noted that even brief exposure without proper ventilation can lead to discomfort. If working indoors, consider using exhaust fans or air purifiers. It's essential to be aware of environmental guidelines. Improper disposal can lead to pollution.

Always read the safety data sheet (SDS) before use. This document details hazards and emergency measures. Incomplete understanding can lead to accidents. A significant number of incidents arise from misinterpretation of safety protocols. When mixing, do it slowly to avoid splashes. Small spills should be contained immediately to prevent further complications.

Liquid Sulphur Black Usage in Projects

This chart illustrates the distribution of common uses for Liquid Sulphur Black in various projects. The data highlights the most prevalent applications based on survey results.

Step-by-Step Guide to Mixing and Applying Liquid Sulphur Black

Mixing and applying Liquid Sulphur Black can seem daunting at first. However, with a step-by-step approach, it becomes more manageable. Start by gathering all necessary tools: measuring cups, a stirring stick, and gloves. Safety is crucial, so always wear protective gear. Next, measure the appropriate amount of Liquid Sulphur Black. This step is vital; too much can overwhelm your project.

When mixing, combine the sulphur with a compatible solvent. Stir thoroughly to achieve a uniform consistency. Don’t rush this process; uneven mixing can lead to poor application. If you notice clumps, keep stirring. It might take longer, but a smooth mixture is key.

Applying the mixture requires attention. Use a brush or spray for even coverage. Take your time with each stroke. Some areas may absorb more color, resulting in unevenness. That's okay—it happens. You can always go back and touch up.

Tips: Test a small area first. This will help you gauge the color. Patience is essential. Don’t be disheartened if the first attempt isn’t perfect. Errors can lead to discoveries. Reflect on what worked and what didn’t, and improve for next time.

Cleaning and Maintenance After Using Liquid Sulphur Black in Projects

Cleaning and maintaining your workspace after using liquid sulphur black is crucial. This product can leave behind residues that may be harmful if not properly handled. Studies suggest that impurities can accumulate in equipment, leading to decreased effectiveness. It's essential to clean surfaces thoroughly to avoid cross-contamination in future projects.

Begin by wearing appropriate protective gear. This may include gloves and masks to avoid contact with fumes. Dust and residual liquid sulphur black can cause irritation. Use water and a mild detergent for cleaning. Ensure all tools and containers are rinsed well. Reports indicate that over 30% of users neglect cleaning, resulting in poor outcomes in subsequent applications.

After cleaning, inspect your workspace. Look for any spots that might need more attention. Areas with stubborn stains may require repeated scrubbing. Pay close attention to corners and crevices, as residue can linger there. Reflecting on your cleaning process can enhance future project efficiency. Some users find it beneficial to create a checklist for cleaning, ensuring nothing is overlooked. Maintain a clean environment; it impacts your project's success significantly.