About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

7 Key Advantages of Utilizing the Best Seal Packing Machine for Your Production Line

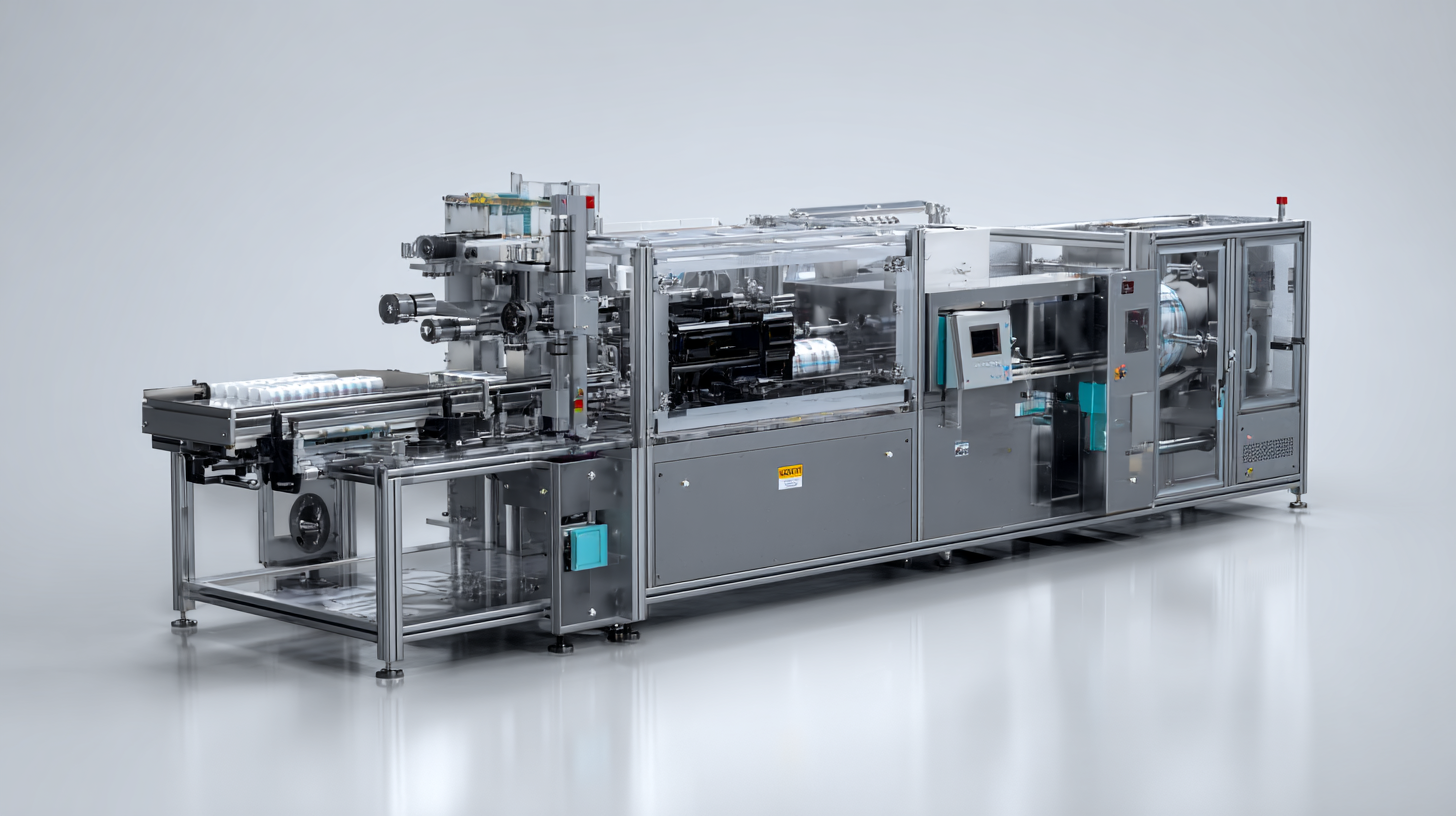

In today's competitive manufacturing landscape, the efficiency and reliability of production processes are paramount. One crucial element that can significantly enhance these processes is the seal packing machine. This advanced equipment not only ensures that products are securely packaged but also plays a pivotal role in maintaining product integrity during storage and transportation. By examining various industry applications, we can uncover the seven key advantages of utilizing the best seal packing machine for your production line. From reducing labor costs and minimizing material waste to improving packaging speed and enhancing product shelf life, the benefits of integrating a top-quality seal packing machine are manifold. This blog will delve into these advantages, offering insights into how they can transform your packaging operations and ultimately contribute to your business's success.

Table of Contents

[Hide]

Understanding the Importance of Quality Seal Packing Machines in Production

In the fast-paced world of manufacturing, the importance of quality seal packing machines cannot be overstated. These machines are essential in ensuring that products remain fresh and secure during transportation and storage. According to a report by Markets and Markets, the global packaging machinery market is projected to reach $45.4 billion by 2027, underscoring the growing recognition of automated packing solutions. High-quality seal packing machines not only enhance product shelf life but also significantly reduce product spoilage, which can account for up to 10% of total production costs in some industries.

Investing in the best seal packing machine leads to streamlined operations and increased efficiency. By automating the sealing process, manufacturers can achieve higher output rates and ensure consistent quality. A study by Smithers Pira found that implementing advanced packing technologies can improve packaging efficiency by 25%.

Tip: When selecting a seal packing machine, consider features such as speed, versatility, and ease of cleaning, which can further enhance productivity. Additionally, training your operators on the machine's optimal use can prevent costly errors and increase overall performance. Remember, the right packing solution goes beyond sealing—it's about protecting your investment in quality.

7 Key Advantages of Utilizing the Best Seal Packing Machine

This bar chart illustrates the key advantages of utilizing high-quality seal packing machines in production lines. Each advantage is scored on a scale of 1 to 10, providing a visual representation of their significance in enhancing productivity and reducing operational costs.

Identifying Key Features of a Reliable Seal Packing Machine

When selecting the best seal packing machine for your production line, it’s essential to focus on the key features that ensure reliability and efficiency. Firstly, look for machines equipped with advanced sealing technology. This includes consistent temperature control and the ability to adapt to various packaging materials. A reliable seal packing machine should create tight seals that are resistant to leaks, guaranteeing product integrity during transit and storage.

Another critical feature is automation capability. An efficient machine should streamline the packing process, significantly reducing manual labor and increasing output. Integrating user-friendly interfaces and programmable settings allows operators to customize the machine for different products easily. Additionally, opt for a machine that offers robust support and maintenance services, ensuring any issues can be swiftly resolved without affecting your production line's workflow. The right seal packing machine not only enhances productivity but also ensures that your products are packed securely for optimal delivery.

7 Key Advantages of Utilizing the Best Seal Packing Machine for Your Production Line

| Advantage | Description | Key Features | Efficiency Improvement |

|---|---|---|---|

| Increased Speed | Enhances production lines by reducing packaging cycle time. | High-speed operation, automation features | Up to 50% faster than manual packing |

| Consistent Quality | Ensures uniformity in packaging, reducing defects. | Precision mechanisms, adjustable settings | Reduction of product waste by 30% |

| Cost Efficiency | Reduces labor costs and material waste significantly. | Low operational costs, long-lasting parts | Return on investment in less than 2 years |

| Versatility | Suitable for various product sizes and materials. | Adjustable parameters, multi-format capabilities | Adaptable to multiple production lines |

| User-Friendly Interface | Simplifies operation with easy controls and tutorials. | Touchscreen controls, guided setup | Reduced training time for operators by 40% |

| Enhanced Safety | Comes with features to minimize workplace accidents. | Safety guards, emergency stops | Increased safety compliance ratings |

| Improved Sustainability | Utilizes eco-friendly materials and processes. | Biodegradable options, energy-saving modes | Decreases carbon footprint by 20% |

Evaluating Supplier Reputation and Industry Experience

When evaluating suppliers for seal packing machines,

reputation and industry experience should be at the forefront of your decision-making process.

A well-established supplier with a strong track record indicates reliability and trustworthiness in their products and services.

This can lead to peace of mind, knowing that you're investing in machinery that has been vetted by previous customers.

Look for reviews, testimonials, and case studies that highlight the supplier's history in the market and their ability to meet customer needs effectively.

Industry experience also plays a vital role in selecting the right seal packing machine.

Suppliers with extensive background knowledge typically possess a deeper understanding of specific industry requirements and regulatory standards.

This experience allows them to offer tailored solutions that enhance productivity and efficiency for your production line.

Moreover, seasoned suppliers are more likely to provide excellent customer support, including installation, training, and ongoing maintenance,

ensuring that your operations run smoothly and minimizing downtime in the long run.

Comparing Cost vs. Quality: Making the Right Choice

When it comes to selecting a seal packing machine for your production line, the age-old debate of cost versus quality often arises. While it might be tempting to choose the most cost-effective option available, it's essential to consider how the machine's quality directly impacts your operational efficiency and product integrity. A high-quality seal packing machine not only enhances the durability of your packaging but also reduces the likelihood of product waste and costly downtimes often associated with inferior machines.

Investing in a premium seal packing machine can lead to long-term savings that outweigh the initial expenditure. Machines that are built to last typically feature better technology, which translates to faster packaging speeds, higher accuracy, and lower maintenance needs. In contrast, lower-cost machines may save money upfront but might require more frequent repairs and replacements, ultimately undermining your productivity and profitability. The right choice is about balancing these factors and recognizing that a worthwhile investment in quality can significantly optimize your production process.

Building Long-Term Relationships with Seal Packing Machine Suppliers

Building long-term relationships with seal packing machine suppliers is integral to optimizing production processes. A recent industry report indicated that companies that foster solid partnerships with their suppliers can improve operational efficiency by up to 30%. This relationship allows manufacturers to gain insights into the latest technologies and innovations in seal packing machines, which can lead to increased productivity and reduced downtime. When suppliers understand a company’s specific needs and challenges, they can provide tailored solutions that enhance the overall production line effectiveness.

Moreover, maintaining consistent communication with suppliers can lead to favorable terms and conditions, including better pricing and priority access to new products. According to a survey from the Packaging Machinery Manufacturers Institute (PMMI), 65% of professionals believe that a strong supplier relationship positively impacts their business's agility in responding to market demands. By investing in long-term partnerships, companies can not only ensure they are using the best available technology for seal packing but also create a responsive support network that can address issues swiftly, securing a competitive edge in the marketplace.