About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

What is a Food Sealer Machine and How Does It Work for Freshness?

In the realm of food preservation, the "food sealer machine" has emerged as an indispensable tool for both home cooks and culinary professionals. This innovative device not only extends the shelf life of various perishable items but also helps maintain their taste and nutritional value over time. According to industry expert Dr. Sarah Thompson, a leading food scientist, "Using a food sealer machine can reduce food waste significantly while ensuring that your ingredients stay fresh for longer periods." This sentiment underscores the growing importance of sealing technology in a world where food sustainability is increasingly prioritized.

The food sealer machine works by removing air from specially designed bags or containers, thereby creating a vacuum seal that protects food from spoilage and freezer burn. By preventing the oxygen from deteriorating food quality, users can enjoy fresh ingredients reminiscent of their original state, whether they are storing meats, vegetables, or prepared meals. As awareness of food preservation methods rises, the food sealer machine stands out as a practical solution to enhance the longevity of our culinary staples and decrease reliance on single-use plastics.

Table of Contents

[Hide]

What is a Food Sealer Machine?

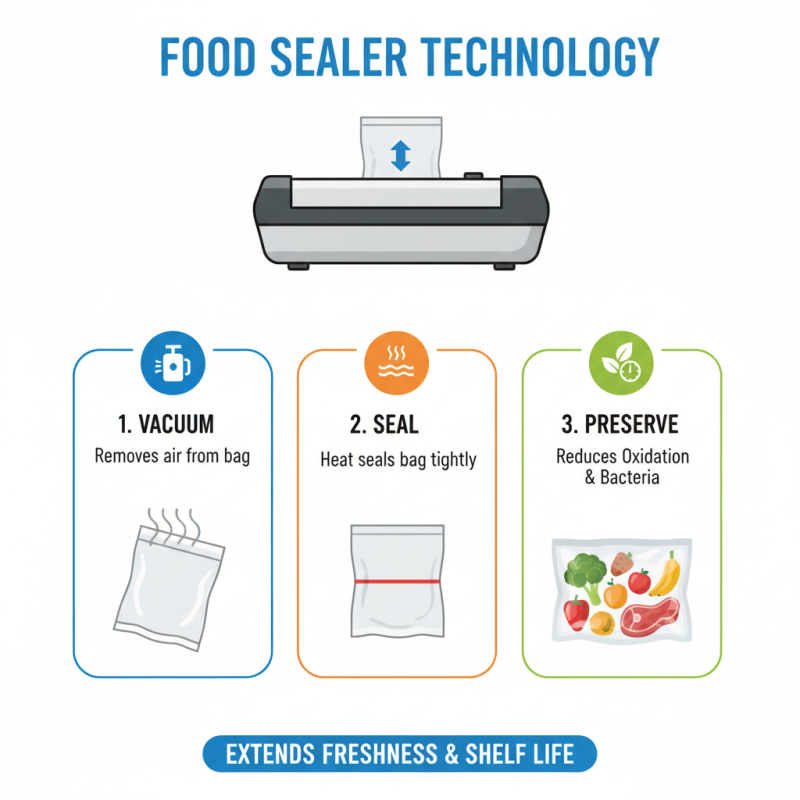

A food sealer machine is an innovative appliance designed to extend the freshness and shelf life of various food items. By removing air from specially designed bags and sealing them tightly, these machines create a vacuum environment that significantly reduces oxidation and bacterial growth. The fundamental components of a food sealer include a vacuum pump, a heat sealing element, and the bags themselves, which are typically made from durable, puncture-resistant materials.

Food sealers can come in various types, including handheld models and countertop machines. Users can easily operate these devices by placing the food items in the bag, inserting the bag into the machine, and initiating the vacuum sealing process with the push of a button. This method not only preserves the quality and flavor of the food but also minimizes food waste by allowing for bulk storage and meal prepping. Whether for fruits, vegetables, meats, or leftovers, a food sealer machine proves to be an essential tool for anyone looking to maintain the freshness of their food efficiently.

The Importance of Food Preservation for Freshness

Food preservation plays a vital role in maintaining the freshness and nutritional value of perishable items. According to the USDA, approximately 30-40% of the food supply in the United States is wasted annually, primarily due to spoilage. This alarming statistic underscores the critical need for effective food preservation methods. Using a food sealer machine, which removes air from packaging and creates an airtight seal, can significantly extend the shelf life of both dry and moist foods. Studies show that vacuum-sealed items can last up to five times longer than their non-sealed counterparts, ensuring that consumers can enjoy fresh ingredients without frequent trips to the store.

The importance of food preservation extends beyond just reducing waste; it also impacts food safety. The Centers for Disease Control and Prevention (CDC) estimates that one in six Americans gets sick from foodborne illnesses each year. Proper preservation techniques, such as vacuum sealing, significantly minimize the risk of bacterial growth and spoilage. By effectively sealing food, a food sealer machine not only maintains freshness but also protects against contaminants, allowing families to enjoy healthy, safe meals with less risk. Thus, investing in a food sealer machine is not only a smart economic choice but also a necessary step towards better food management and safety.

How Food Sealers Work: The Vacuum Sealing Process

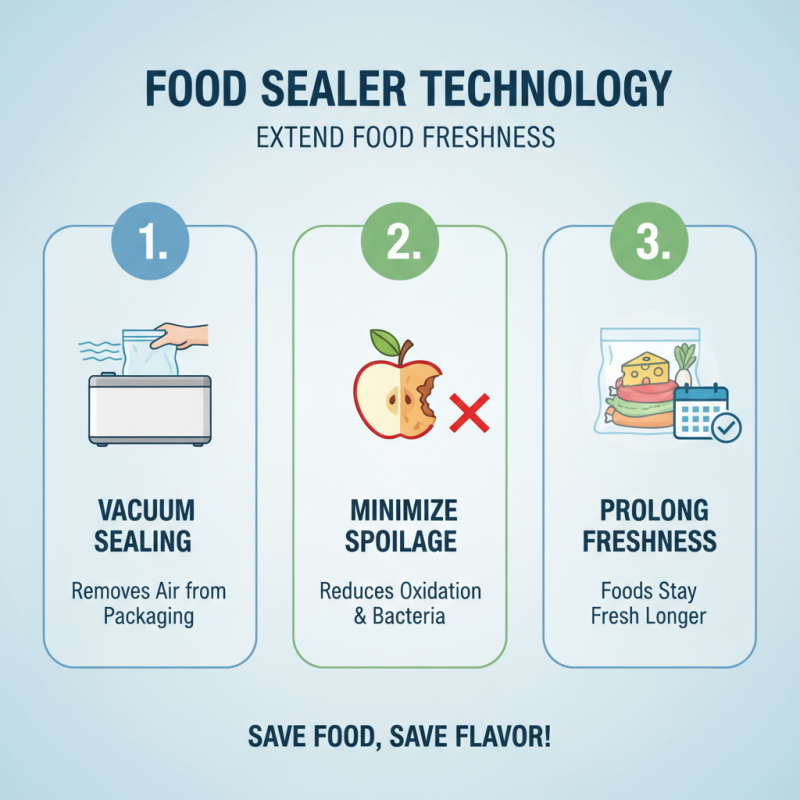

A food sealer machine is designed to prolong the freshness of foods by creating a vacuum-sealed environment. The vacuum sealing process is the heart of this technology, where air is removed from the packaging to minimize oxidation and inhibit the growth of bacteria and mold. This method effectively reduces spoilage, allowing foods to maintain their flavor and nutritional value for an extended period.

The process begins with placing food in a specially designed plastic bag or pouch. The machine then clamps down on the bag, creating a tight seal. As it operates, a vacuum pump removes air from the bag, creating a low-pressure environment. Once the air is removed, the machine heat-seals the open end of the bag, ensuring no air can re-enter. This not only preserves the freshness of the food but also makes it easier to store by saving space and preventing freezer burn when storing perishable items. Through this innovative technique, food sealers provide a practical solution for both home cooks and professional chefs aiming to reduce waste and enhance food storage efficiency.

Benefits of Using a Food Sealer for Storage and Freshness

A food sealer machine is an essential tool in modern kitchens, designed to extend the shelf life of food by vacuum sealing it in airtight bags. This process significantly slows down oxidation, which is a key factor in food spoilage. According to the USDA, vacuum sealing can prolong the freshness of food by 1-2 years longer than traditional storage methods. By removing air from packaging, food sealers help preserve the flavor, color, and texture of various food items, making it an excellent investment for households looking to reduce food waste.

The benefits of utilizing a food sealer for storage and freshness are substantial. A report from Food Keeper states that using vacuum-sealed bags can prevent freezer burn and spoilage, thereby retaining up to 90% of the food's original quality over time. For instance, meats sealed in a food saver can last 1-3 years in the freezer, compared to only 4-12 months when stored in typical packaging. Moreover, vacuum-sealed fruits and vegetables not only retain their nutrients but also minimize the risk of bacterial growth, ensuring that meals prepared in advance remain safe and delicious.

Types of Food Sealer Machines and Their Features

When considering food preservation, understanding the types of food sealer machines available is crucial. The most common types include vacuum sealers, heat sealers, and chamber sealers. Vacuum sealers remove air from the packaging, which significantly extends the shelf life of food items by slowing down the oxidation process. Heat sealers work by sealing pre-made bags using heat, making them a convenient option for smaller tasks. Chamber sealers, on the other hand, are ideal for commercial use as they can handle large quantities and different types of food items.

Here are a few tips for choosing the right machine: First, consider the volume of food you typically store—if you’re sealing large batches, a chamber sealer might be the best investment. Additionally, think about the types of food you'll be sealing. Some machines are better suited for moist foods, while others excel with dry items. Finally, pay attention to ease of use; a user-friendly interface can make your sealing tasks much more efficient.

Maintaining your food sealer is vital for optimal performance. Regularly clean the sealing strip and check for wear and tear on the bags. It's also important to store your sealer in a dry place to avoid any moisture-related damage. By taking these steps, you can ensure your food stays fresh longer and you get the most out of your food sealer machine.

| Type of Food Sealer | Working Mechanism | Key Features | Recommended Uses |

|---|---|---|---|

| Vacuum Sealer | Removes air from the package and seals it tightly. | Automatic operation, adjustable vacuum levels, heat sealing strip. | Meat storage, sous vide cooking, long-term food preservation. |

| chamber Sealer | Seals bags within a chamber and evacuates air environment. | High vacuum strength, ability to seal liquids, customizable settings. | Commercial use, large food batches, packaging liquids. |

| Handheld Sealer | Portable device to seal bags by removing air manually. | Compact size, easy operation, battery-operated options. | Travel, small food portions, quick storage solutions. |

| External Sealer | Seals bags by applying heat while using a vacuum pump outside. | Affordable, user-friendly, compatible with various bag sizes. | Home use, occasional sealing tasks, small kitchens. |

Related Posts

-

Unmatched Quality in Global Markets with the Best Food Packaging Sealing Machine from China

-

Navigating Import Export Certifications for the Best Cryovac Machine Choices Worldwide

-

5 Essential Tips for Maximizing the Efficiency of Your Cryovac Machine

-

Innovative Food Sealer Machines Transforming Food Preservation at the 138th Canton Fair in 2025

-

Unlocking Freshness: How Food Sealer Machines Revolutionize Your Storage Habits

-

Understanding the Benefits of Cryovac Machines for Food Preservation Techniques