About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

How to Choose the Right Bag Sealer Machine for Your Packaging Needs

In the dynamic world of packaging, selecting the appropriate equipment is vital for maintaining product integrity and efficiency. Among these tools, the bag sealer machine plays a crucial role, significantly impacting product shelf life and reducing waste. According to a report by Grand View Research, the global packaging machinery market was valued at approximately $45 billion in 2020 and is expected to grow steadily, driven by the increasing demand for automated solutions in various industries. Specifically, the use of bag sealing technologies is projected to rise as businesses prioritize quality and sustainability in their packaging processes. As companies strive to optimize operations and meet consumer expectations, understanding the different types of bag sealer machines and their functionalities becomes essential for selecting the right one that meets specific packaging needs.

Table of Contents

[Hide]

Understanding Different Types of Bag Sealer Machines Available in the Market

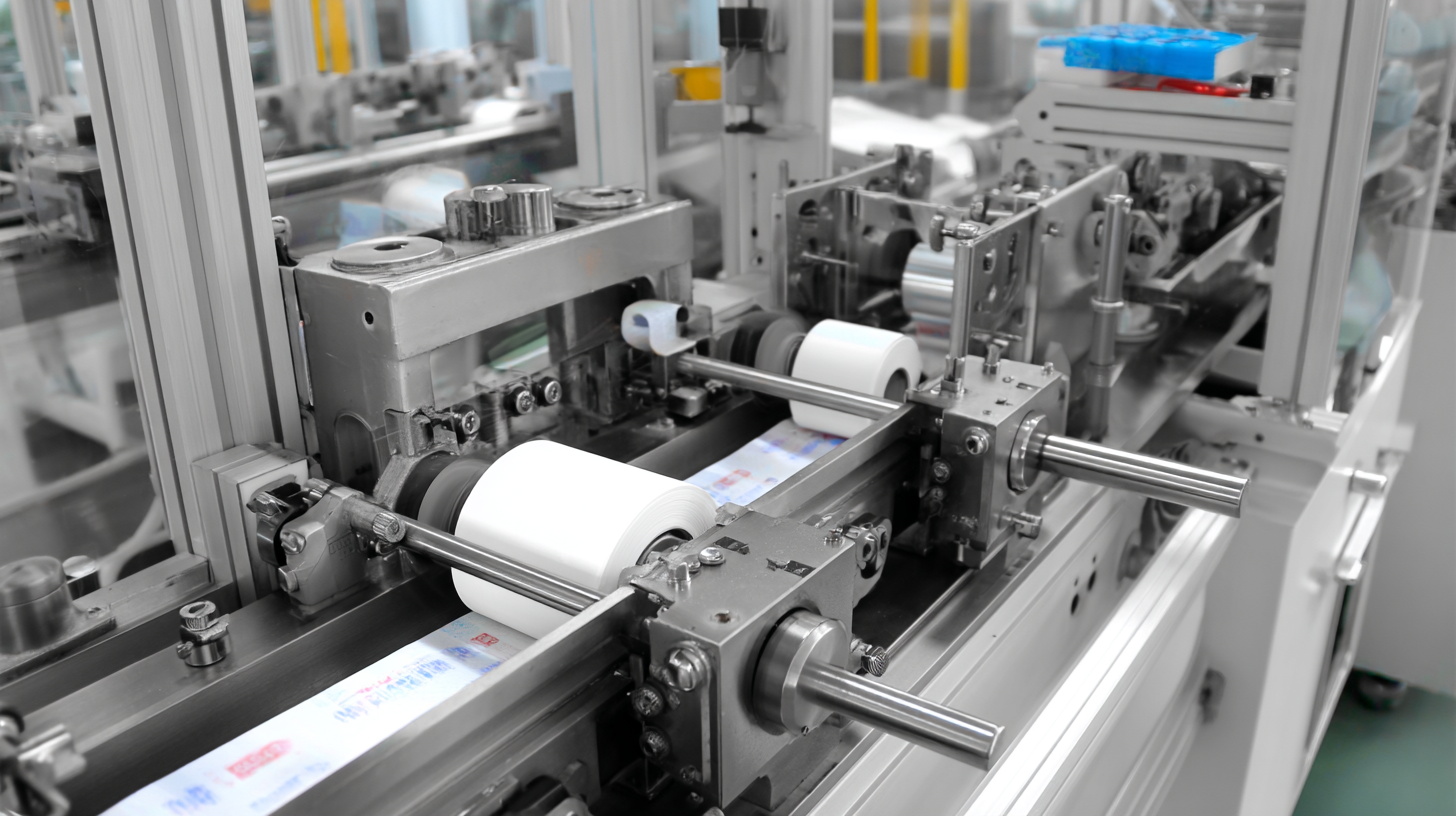

When selecting a bag sealer machine, it's essential to understand the different types available in the market to meet your specific packaging needs. One of the most common types is the heat sealers, which utilize heat to weld the edges of plastic bags. These machines are ideal for sealing polyethylene and polypropylene bags, making them suitable for industries ranging from food packaging to pharmaceuticals. They come in various forms, such as impulse sealers and continuous sealers, each with specific speed and capacity advantages.

Another type is the vacuum sealing machine, which removes air from the bag before sealing. This method is excellent for preserving perishable items by extending their shelf life and preventing freezer burn. It’s particularly beneficial in food packaging for restaurants and meal preparation businesses. Finally, there are band sealers, which are designed for high-volume operations, providing a reliable and professional finish. These machines can seal bags of various sizes and are often used in manufacturing settings. Selecting the right type depends on the volume of production, the nature of the products being sealed, and the required level of preservation.

How to Choose the Right Bag Sealer Machine for Your Packaging Needs

| Machine Type | Seal Method | Suitable Material | Production Speed (bags/min) | Price Range ($) |

|---|---|---|---|---|

| Impulse Sealers | Heat Sealing | Plastic, Mylar | 5-15 | 50-150 |

| Continuous Band Sealers | Heat Sealing | Foil, Plastic | 10-30 | 200-500 |

| Vacuum Sealers | Vacuum Sealing | Plastic, Mylar | 5-10 | 100-300 |

| Cup Sealers | Heat Sealing | Plastic Cups | 15-25 | 150-400 |

| Clamping Sealers | Heat Sealing | Paper, Polyethylene | 5-20 | 75-200 |

Key Features to Consider When Selecting a Bag Sealer Machine

When selecting a bag sealer machine, several key features must be considered to ensure it meets your packaging needs efficiently. First, sealing method is crucial; options include impulse sealing, continuous sealing, and vacuum sealing. According to industry reports, impulse sealers account for over 40% of the market due to their versatility and ability to operate in various settings, making them suitable for businesses with diverse product ranges.

Another important consideration is the sealing width and thickness capability. Machines that can handle a wider range of seal widths tend to be more versatile, accommodating different bag sizes. Data suggests that businesses with fluctuating production demands often benefit from machines with adjustable sealing parameters. Lastly, ease of use and maintenance should not be overlooked. Machines designed with user-friendly interfaces and accessible components can significantly reduce downtime and enhance production efficiency, as noted in a recent survey of packaging industry professionals where ease of operation was rated as a top priority by 65% of respondents.

Bag Sealer Machine Key Features Comparison

Determining the Right Size and Capacity for Your Packaging Needs

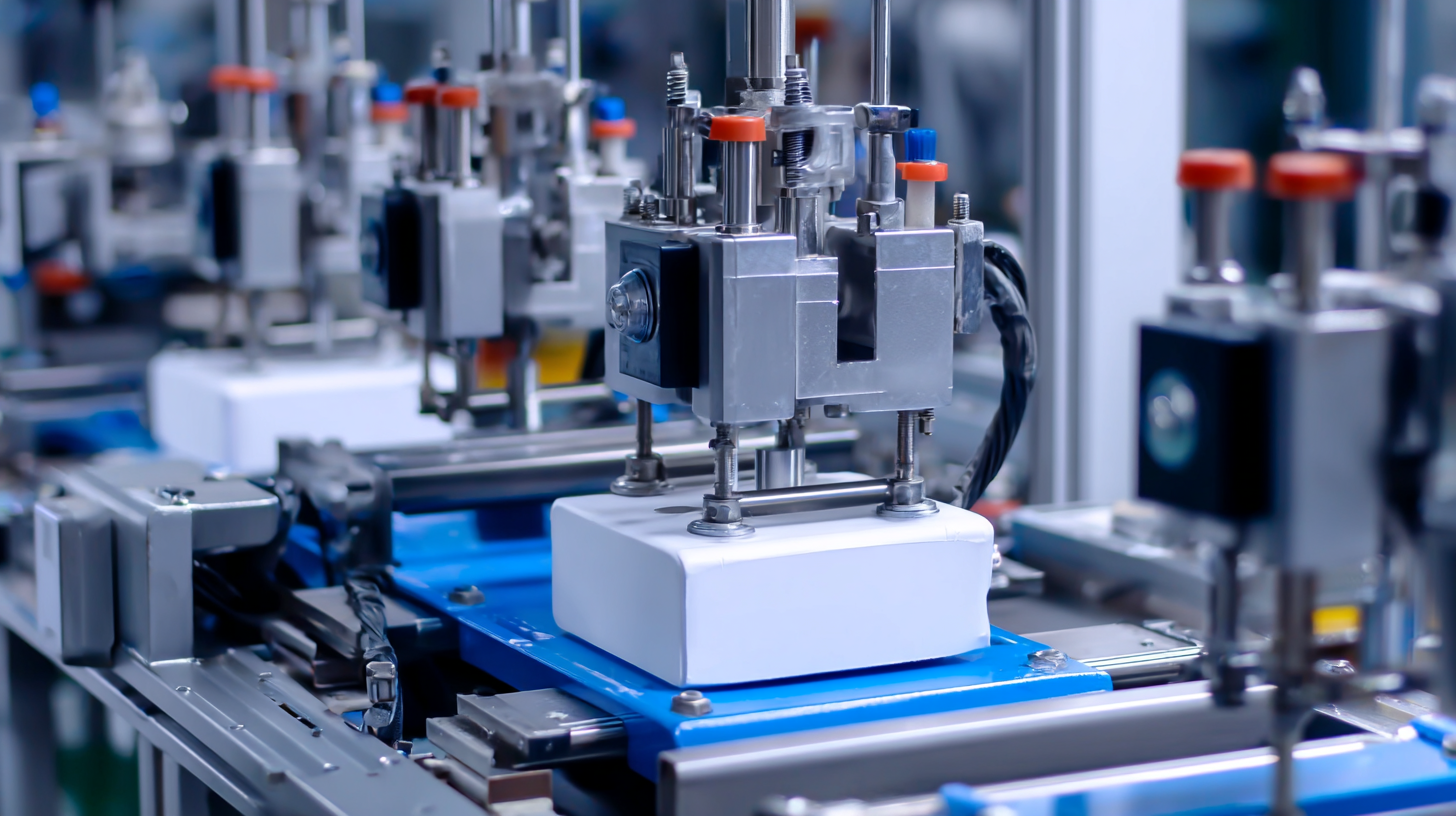

When selecting a bag sealer machine, determining the right size and capacity is crucial to meet your packaging needs effectively. First, consider the dimensions of the bags you will be sealing. Bag sealers come in various sizes, and choosing a machine that can accommodate both the width and length of your packaging will ensure efficient sealing. A machine too small may lead to frequent adjustments and inefficiencies, while a larger one can consume unnecessary space.

In addition to size, the capacity of the bag sealer should match your production volume. Assess how many bags you need to seal per hour to avoid bottlenecks in your packaging line. If you have high throughput demands, opting for a machine with a higher sealing capacity will enhance productivity and minimize downtime. Conversely, for smaller operations, a compact, lower-capacity machine may suffice. By carefully evaluating these aspects, you can select a bag sealer that aligns perfectly with your operational requirements.

Evaluating Cost vs. Quality: Finding the Best Value Bag Sealer

When selecting a bag sealer machine, it’s crucial to evaluate the balance between cost and quality to ensure you find the best value for your packaging needs. Many businesses may be tempted to choose the cheapest option available, but this approach can lead to compromised quality, potentially affecting product integrity. A lower price often correlates with reduced durability and efficiency, which can result in higher long-term costs due to frequent replacements or repairs. Therefore, it is essential to consider not just the initial investment but also the machine's performance over time.

On the other hand, investing in a higher-quality bag sealer machine may seem daunting due to its upfront cost, but it can deliver substantial benefits. These machines are typically built with better materials and advanced technology, providing consistent sealing quality and faster operation speeds. As a result, they can enhance productivity and reduce waste caused by improperly sealed bags. Businesses should weigh their specific packaging demands against available options, ensuring that they choose a machine that offers the best return on investment while meeting their operational standards.

Maintaining Your Bag Sealer Machine for Long-Term Efficiency and Durability

Maintaining your bag sealer machine is crucial for ensuring its long-term efficiency and durability. Regular maintenance not only extends the lifespan of the machine but also enhances its performance, resulting in consistently high-quality seals. To achieve this, it's essential to create a routine maintenance schedule that includes cleaning the sealing elements to prevent buildup of debris and residue, checking for any wear and tear on the parts, and lubricating moving components when necessary. By taking these proactive steps, you can minimize the risk of malfunctions and unexpected downtime.

Another important aspect of maintenance is monitoring the machine's operational settings. Properly calibrating the temperature and pressure settings based on the materials being sealed can prevent damage to both the machine and the bags. It's also advisable to conduct regular inspection of electrical components and connections to ensure safe operations. Keeping a log of maintenance activities and machine performance can help identify potential issues early on and allow for timely interventions, ensuring that your bag sealer continues to operate at peak efficiency.

Related Posts

-

5 Top Reasons Why the Best Bag Sealer Machine is Essential for Global Procurement

-

Unmatched Quality in Global Markets with the Best Food Packaging Sealing Machine from China

-

How to Choose the Best Food Vacuum Sealer for Your Kitchen Needs

-

How to Choose the Best Commercial Food Sealer for Your Business Needs

-

Unlocking the Advantages of the Best Commercial Food Vacuum Sealer for Your Business

-

Navigating Export and Import Certifications for the Best Commercial Vacuum Packing Machines in Global Markets