About Us | Blog | FAQs | Tips/Troubleshoot | Contact Us | Machine Manuals | Demo Videos

Ultimate Guide to Choosing the Best Industrial Vacuum Sealer Machine for Your Business

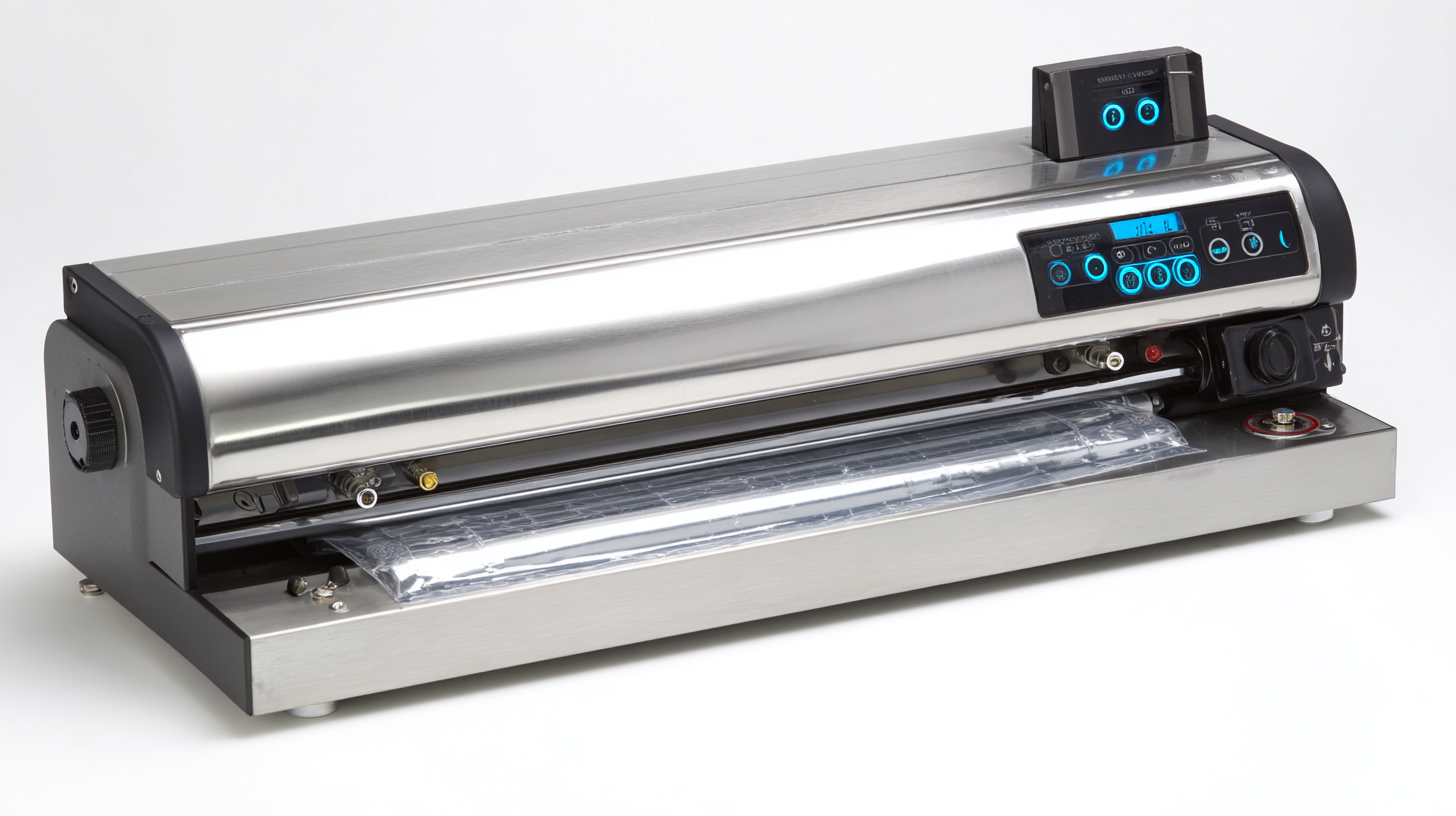

In today's competitive marketplace, choosing the right industrial vacuum sealer machine is crucial for enhancing operational efficiency and ensuring product longevity. As businesses increasingly prioritize quality and reliability, the demand for top-notch vacuum sealers has surged, with Chinese manufacturing leading the charge in delivering exceptional products. This ultimate guide aims to navigate you through the essential factors to consider when selecting the best industrial vacuum sealer machine for your business needs. From understanding the various features and specifications to determining how to optimize your production process, this comprehensive resource will equip you with the knowledge necessary to make an informed decision. Whether you're in the food processing, pharmaceuticals, or any other sector requiring robust sealing solutions, this guide is designed to highlight the best options available globally, with a particular focus on the high-quality offerings from China.

Table of Contents

[Hide]

Key Features to Consider When Selecting an Industrial Vacuum Sealer

When selecting an industrial vacuum sealer machine for your business, it's essential to focus on key features that align with your operational needs. Firstly, consider the sealing strength and the type of materials you intend to use. According to the Food Packaging Association, strong seals reduce the risk of product spoilage and extend shelf life by up to 50%. An ideal machine should have adjustable pressure settings to accommodate different pouch materials, ensuring versatility across various applications.

Another critical feature is the machine's capacity and throughput. The Packaging Machinery Manufacturers Institute reports that businesses with high-volume demands can benefit from machines with faster cycle times and larger sealing bars. This can significantly enhance productivity, allowing for the processing of thousands of units daily without compromising on quality. Furthermore, investing in models with built-in maintenance alerts can prevent downtime and extend the equipment's lifespan, making it a savvy choice for operational efficiency.

Key Features to Consider When Selecting an Industrial Vacuum Sealer

This bar chart represents essential features to consider when selecting an industrial vacuum sealer. It includes sealing speed, maximum chamber size, pump power, weight, and price, providing a visual overview to assist businesses in making informed decisions.

Understanding Different Types of Industrial Vacuum Sealers and Their Uses

When selecting an industrial vacuum sealer, understanding the various types and their specific applications is crucial for optimizing your business operations.

The two main types of vacuum sealers are chamber vacuum sealers and external vacuum sealers. Chamber vacuum sealers are typically preferred for their ability to efficiently seal liquids and moist foods without compromising quality, making them ideal for restaurants and food processing industries. External vacuum sealers, on the other hand, are often used for dry items and are more portable, suitable for smaller operations or home use.

According to market research, the global vacuum packaging market is projected to reach a staggering $50.04 billion by 2032, indicating a significant demand for efficient food preservation methods. This growth highlights the importance of investing in the right vacuum sealer for your needs.

Tips for Choosing the Right Industrial Vacuum Sealer:

- Assess the types of foods you will be sealing: If you're working with liquids, a chamber vacuum sealer is the best choice.

- Consider your volume needs: For high-volume sealing, look for more robust machines that can handle regular operation without overheating.

- Don’t overlook user-friendliness: A machine that is easy to operate will save you time and reduce the likelihood of user errors.

Evaluating Your Business Needs: Size, Capacity, and Production Goals

When selecting the right industrial vacuum sealer machine for your business, evaluating your specific needs is crucial. Consider factors such as size, capacity, and production goals. According to a recent report by Technavio, the global vacuum packaging market is projected to grow by over $3 billion from 2020 to 2024, highlighting the increasing demand for efficient packaging solutions in various industries. A machine that aligns with your production scale can significantly enhance operational efficiency.

**Tip:** Assess your production volume. If you're processing large quantities of products daily, opt for a machine with a higher capacity to avoid bottlenecks. Look for machines that offer adjustable sealing cycles to accommodate different product types.

Another important consideration is the size of the machine and your workspace. Space constraints in your facility can limit your options. According to a survey by PMMI, 63% of packaging machine users reported that space and equipment layout directly influenced their purchasing decisions. Therefore, ensure that the machine you choose not only fits well within your workspace but also aligns with your long-term production goals.

**Tip:** Measure your workspace before shopping. Opt for models that provide compact designs or multifunctionality to save space while meeting your production needs effectively.

Comparing Cost vs. Value: Making an Informed Investment Decision

When it comes to investing in an industrial vacuum sealer machine, understanding the cost versus value is crucial. According to a report from PMMI, the total U.S. packaging machinery market was valued at $8.7 billion in 2020 and is projected to grow at a CAGR of 2.7% through 2025. This growth underlines the importance of selecting the right machinery that not only fits your budget but also meets the long-term operational needs of your business.

An effective vacuum sealer can enhance product shelf life, reduce waste, and streamline packaging processes, ultimately contributing to increased profitability. Research by Grand View Research indicates that businesses utilizing advanced sealing technology report a 20-30% reduction in spoilage and returns. Therefore, the initial investment in a high-quality vacuum sealer, while potentially higher than basic models, can yield substantial savings and improved efficiency over time, making it a smart financial decision for businesses aiming for sustainable growth.

Ultimate Guide to Choosing the Best Industrial Vacuum Sealer Machine for Your Business - Comparing Cost vs. Value

| Model | Price ($) | Vacuum Strength (Hg) | Sealing Speed (items/min) | Warranty (Years) | Customer Rating (out of 5) | Value for Money (1-10) |

|---|---|---|---|---|---|---|

| Model A | 1500 | 27 | 5 | 2 | 4.5 | 8 |

| Model B | 2000 | 29 | 6 | 3 | 4.8 | 9 |

| Model C | 1000 | 25 | 4 | 1 | 4.0 | 7 |

| Model D | 1750 | 28 | 5 | 2 | 4.6 | 8 |

Maintenance and Support: Ensuring Longevity of Your Vacuum Sealer Machine

When investing in an industrial vacuum sealer machine, understanding the importance of maintenance and support is crucial for ensuring the longevity and efficiency of your equipment. Regular upkeep not only prevents unexpected breakdowns but also maintains the quality of your sealing process. Routine maintenance should include cleaning the vacuum chamber, checking for wear on the sealing bars, and inspecting the gaskets. This proactive approach can save your business from costly repairs and downtime, ultimately boosting productivity.

Moreover, having reliable support from the manufacturer or supplier plays a vital role in the operational lifespan of your vacuum sealer. Opting for a brand that offers comprehensive customer support, including access to spare parts and expert advice, can provide peace of mind when issues arise. Additionally, consider investing in a service plan that includes regular check-ups and maintenance services. By prioritizing maintenance and establishing a solid support system, businesses can ensure their vacuum sealer machine remains a valuable asset in their production line for years to come.